Leak Tester for Easy Open Ends

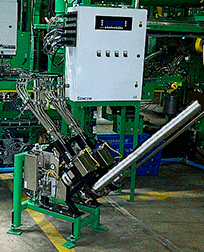

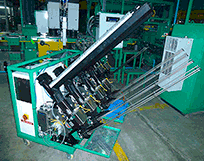

MLT – Micro Leak Tester

ON OR OFF-LINE SAMPLE TESTER FOR DETECTING MICRO LEAKS IN CONVERTED ENDS

The best balance of sampling speed, sensitivity, and running costs, offering the most practical and economic solution to detecting micro-leaks in can lids.

MLT is a real time micro leak detector for beverage and food ends (diameter range: 113-502 / 45mm-127mm). Leak rate capability is set to ensure a non-destructive test that minimizes false rejects and does not require a wet seal or excessive test pressures that damage the product. Sencon believe that MLT’s air pressure test achieves the best balance of sampling speed, sensitivity and running costs, offering the most practical and economic solution to detecting micro-leaks in can lids.

Failure to detect leaks in lids leads to massive re-checking jobs or customer complaint. 100% light testing with Sencon’s on-press Light Tester for Easy Open Ends ELTP will find leaks that have a detectable light path through the fault. But micro leaks and more complex faults – like rivet cracks – may not allow light to pass and will go unnoticed. A further test is needed.

BENEFITS & FEATURES

Flexible Installation and Modular Expansion

MLT is a modular system, enabling budgeted purchases and fully compatible system expansion. From 1 to 4 heads can be installed to suit different press configurations.

High Sampling Rate

The online MLT can test 2% of production output with a press speed of 750 ends per minute, per lane.

Low Maintenance, Low Running Costs

Once installed, MLT keeps running reliably. Regular wiping of the test chamber seals being the only maintenance required.

Low False Rejects

All lids rejected by a micro leak detector demand extra attention to confirm the leak and initiate the appropriate action. False rejects therefore waste time through unnecessary investigation. Based on detailed research, Sencon’s MLT micro leak detector is set by default to work at realistic detection thresholds in order to avoid rejecting good product through active monitoring of background noise that allows the system to operate at maximum sensitivity while ensuring minimum false rejects.

Intelligent Sampling for Complete Protection

MLT can automatically adjust its sampling rate to ensure that ends from all belt pocket are being sampled. Sampling from the line at regular, fixed intervals could mean that ends are tested from only one group of belt pockets, as the belt and the sampler fall into synchronization. To avoid this, the on-line MLT has an option called “walk the belt”, which monitors and varies the sampling rate to ensure that lids from every belt pocket are sampled. In this mode, the average sample rate is 15 lids per minute, but overall protection against faulty product is effectively greater.

Related Products

TAB VERIFIER

Detects double shells and missing tabs…

End Counting Sensor

Achieve reliable and highly accurate product counts…

End Gap Control System

Maintains the optimum gap at end downstackers…

Light Tester for Easy Open Ends

100% light testing for leaks on conversion press…

OFFICES

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Email: [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tel: +1 970 305 8721